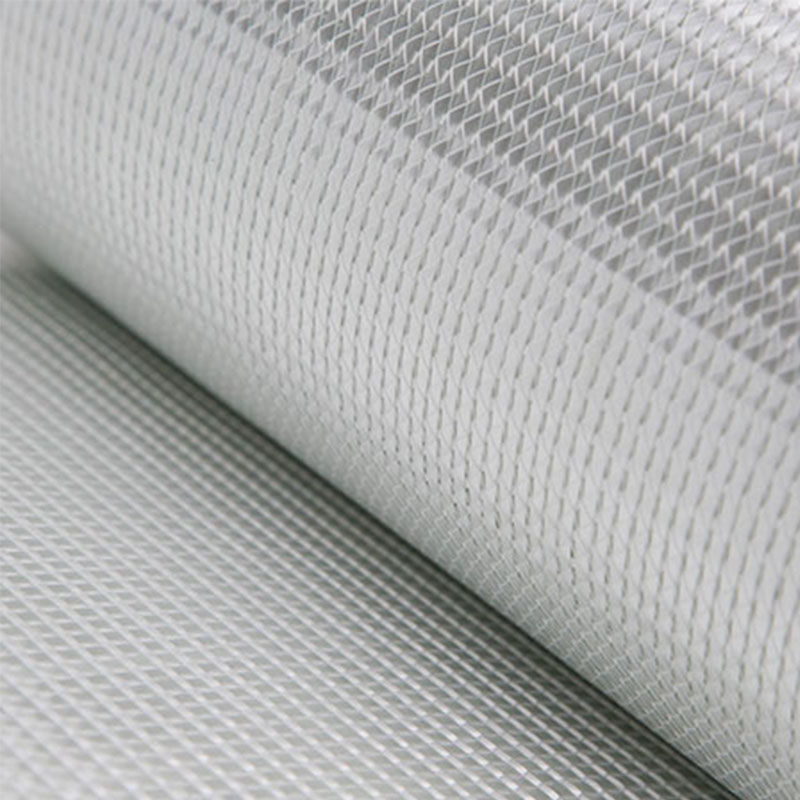

Advantages: Good processability: Vinyl Ester Resin has good processability and can be processed by hand lay-up, lamination, molding and other methods.

Application scenarios: Chemical equipment: Vinyl Ester Resin is often used to make pipes, storage tanks, valves and other components of chemical equipment. It has the advantages of corrosion resistance, high temperature resistance, high pressure resistance, etc.

1. Liquid resin properties (25ºC)

| Project | INV-V411L | Testing method |

| Appearance (visual inspection) | Transparent light yellow liquid | GB/T 8237 |

| Viscosity (mPa.s) | 180-220 | GB/T 7193 |

| Acid value (mg KOH/g) | 4-8 | GB/T 7193 |

| Solid content | 52-56 | GB/T 7193 |

25ºC gel time (min)*

25°C curing exothermic peak (°C) | 30-120(Customized)

100-140 | GB/T 7193 |

* The curing agent uses AKZO M-50, the dosage is 2%, and the accelerator uses AKZO NL 49P (1% Co) 1%.

2. Physical properties of resin castings

| Project | Test value | Testing method |

| Tensile strength (MPa) | 85 | GB/T 2567 |

| Tensile Modulus (GPa) | 3.3 | GB/T 2567 |

| Elongation at break (%) | 5.0 | GB/T 2567 |

| Bending strength (MPa) | 140 | GB/T 2567 |

| Flexural Modulus (GPa) | 3.4 | GB/T 2567 |

| Impact toughness (KJ/m2) | 19 | GB/T 2567 |

| Glass transition temperature Tg (ºC) | 115 | DSC 10ºC/min |

Note:

1) the casting system sample method is implemented according to GB/T 8237;

2) Post-curing treatment of the casting body: room temperature × 24 hours + 100 °C × 3 hours.

3. Matters needing attention

1. The transportation shall comply with the regulations on the transportation and handling of hazardous chemicals in Chapter V of the State Council's "Regulations on the Safety Management of Chemical Hazardous Substances".

2. The product should be stored in a cool place below 25ºC, avoid fire and isolate the heat source.

3. The shelf life is 3 months under the specified storage conditions.

FAQ

Why we choose Changzhou Rule Composite Material Co., Ltd?

our is a enterprise engaged in in manufacturing high-performance unsaturated polyester resin, gel coat, glass fiber reinforced composite materials and other related products, also professional in research, development as well as technical consulting and services of composite materials.

What is resin?

Resin usually refers to products inclined to softening or melting after receiving heat. When softening, it shows a trend toward flowing under the influence of external forces. Under normal temperature, it is in solid, semi-solid state, and sometimes liquid organic polymer. Broadly speaking, any macromolecule compound that can be used as a raw material for plastic processing can be called resin.

What can resins do for you?

Resin products are widely used in sectors like railways, automobiles, wind power, shipbuilding, cooling towers, pipelines, coatings, electrical appliances, artificial stone, handicrafts, lighting tiles, sanitary ware, anti-corrosion engineering and so on. Rule has been granted certification of ISO9001: 2008 Quality Management System and ISO14001: 2004 Environmental Management System, and some products have won recognition of China Classification Society(CCS) and Food-Level Licenses of the Provincial Department of Health.

We are the professional resin solution provider.

With decades of experience in the R & D of resins, we can fully understand customers' needs and aspirations in the cooperation process and have presented countless solutions. Over the years, we work hard to optimize our products and make them attractive to end users.

yomi@rulecomposite.com

yomi@rulecomposite.com